Morris Minor: still big in Sri Lanka

A Sri Lankan factory is doing a roaring trade hand-building parts to keep classic Morris Minors on the road

Bodywork expert Chandrasiri repairs a rear door while a Minor Traveller awaits the finishing touches to its ground-up restoration Photos: PAUL JEFFRIES.

I can’t speak Sinhala and my attempts to pronounce the Sri Lankan place names only met with puzzled expressions. But everyone knew exactly where I wanted to go when I mentioned the ‘Morris Minor Garage’. Just a few miles from the historic town of Galle, in the south of the island, where well-heeled tourists sip lattes in up-market cafés, the company is hand-making repair panels to help keep one of Britain’s best-loved classic cars on the road.

It’s officially known as the Durable Car Company and produces 89 parts for the Minor, from intricate sill sections and cross-members for saloons to complete new chassis for vans and pick-ups. And it has just begun the manufacture of bumper blades in stainless steel.

Established by retired diplomat and Sri Lankan businessman Dhanapala Samarasekara in 1992 with Charles Ware, owner of the eponymous Morris Minor Centre in Bristol to which it supplies its panels, it now employs 21 full- and part-time local people in an area where skilled work is hard to find.

The name reflects the philosophy of its founders who believe it is better to repair something than replace it. Indeed, Samarasekara rails against the planned obsolescence of contemporary cars,

Describing it as “a wastage of human effort”

Surrounded by palm trees, the open-sided factory echoes to the discordant beat of multiple hammers as workers skillfully put the finishing touches to panels cut from sheet steel and pressed into shape on ancient machines. Next to them are stacked shiny new cross-members, sill sections and engine bay panels ready for painting.

In today’s high-tech world, the company’s production methods might appear old-fashioned with its use of rudimentary tooling and emphasis on manual finishing. But it makes economic sense for relatively small production runs, explains director and factory manager, Somasiri.

And to be able to reproduce often complex panels using such simple equipment is a testament to the skill of the workers. Some of them have been trained by the company since leaving school while others boast decades of experience, like senior hand Wimalasiri.

Panels are marked out on sheet steel using a template and cut by hand before being pressed by machine into the required shape using handmade ‘moulds’. Other presses are used to punch out holes or form the folds and dimples that give the panels their rigidity. Final finishing is

Performed with hammers, cold chisels, grinders and files.

Although the focus is on ‘underfloor’ parts, rather than the Minor’s curvaceous wings which would require great investment in machines and tooling, the factory has produced a number of body panels for the rare Minor pick-up. Workers proudly showed me the new rear side panels they had made for a pick-up in the workshop, along with its load floors, bumper flitch panel and

Even the tailgate with its characteristic square dimples.

Unfortunately, Sri Lanka’s climate is not as kind to cars as might be expected; heavy monsoons and salt air on the coast means Minors there rust as badly as those in Britain, if not more so. Which is why the company also carries out full restorations for local enthusiasts.

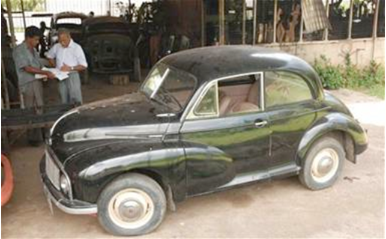

“People who can afford it bring their car to us for refurbishment because they love it,” says Somasiri, pointing to the 1960 black four-door car they’re restoring for the nephew of the country’s president, Mahinda Rajapaksa. “It was a mess!” he recalls. Forgotten for 20 years and hauled in on the back of a truck, it needed extensive work including new floors, chassis sections and body panels.

In charge of restorations is Chandrasiri, a bodywork repair expert who’s worked there for 20 years. Shirtless and sandaled in the midday heat, he fashioned a custom repair section for a rusted door with an ease borne of years of experience. As I watched, he measured, snipped, hammered, checked and hammered again until it fitted like the final piece in a jigsaw. Later he showed me a new gutter section he’d made that looked as if it could have come from the original factory.

Meanwhile, engines and gearboxes are sent away for rebuilding, and replacement mechanical and electrical components are shipped in from the UK. Specialists are brought in to carry out re-

sprays or repair the wood on the timbered Minor Traveler model.

There are estimated to be as many as 4,000 Minors still on the road in Sri Lanka, a far cry from their heyday in the 1960s and 1970s when they provided reliable transport for many families and even served as taxis. “It was very, very popular before the arrival of the Japanese cars recalls Somasiri, himself a former Minor owner. “It was reasonably priced, durable and people were very

Fond of it because it was easy to drive with low running costs “

More than 40 years later and the car still commands great affection in the former British colony, he explains: “People know it as a British car and they believe it is good that it is kept as an antique.”

Little wonder that the Galle bus station manager had beamed with delight when I told him where I wanted to go. Proudly telling me he owned a 1953 Minor, he personally escorted me to the right bus as if I were royalty and gave strict instructions to the conductor to let me off at the Morris Minor Garage.

Courtesy of Paul Jeffries The Telegraph 18 October 2013

Forwarded by Charles Schokman

No Comments