MAKING OF CRICKET BATS – By Dr. Gnana Sankaralingam

Bats are carved specially from white willow (Salix Alba) which is found in Europe and Central Asia. This wood being light in weight, is tough and shock resistant, which means that it could handle high speed impact of a cricket ball without splintering. Tree which is ten years old, and with trunk 10 feet long, is ideal for making bats. Manufacture of bats is a blend of old tradition and modern methods.

Trunk of willow is cut into roughly cricket bat sized chunks known as clefts and then carved into the familiar bat shape. Their ends are dipped in wax and are air dried for up to an year. Clefts are graded then into four levels using the criteria of straightness of the grain, width of the grain, any blemishes etc. Next the cleft goes through pressing process, where a machine slowly compresses it into shape

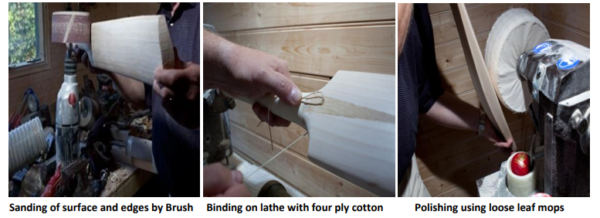

Blade is then spliced at the top and a handle is attached, which is the key in providing it spring like capability. Once shoulders are cut out, specific alterations are made to the timber by hand, such as rounding off the toe and filing away of unnecessary pieces. After edges and face have been sanded down, bat is polished by bee’s wax compound. Handle is bound by string and rubber grip applied.

The rule for the bat is that it should not be more than 38” in length and 4.25” in width. However there is no restriction to weight or thickness. Seasoning of bats is done by applying linseed oil to the flat side. Special bats are in the market such as “Mongoose”, a new type of bat which has extra-long handle and smaller hitting surface, supposed to give more bat speed and much bigger sweet spot.